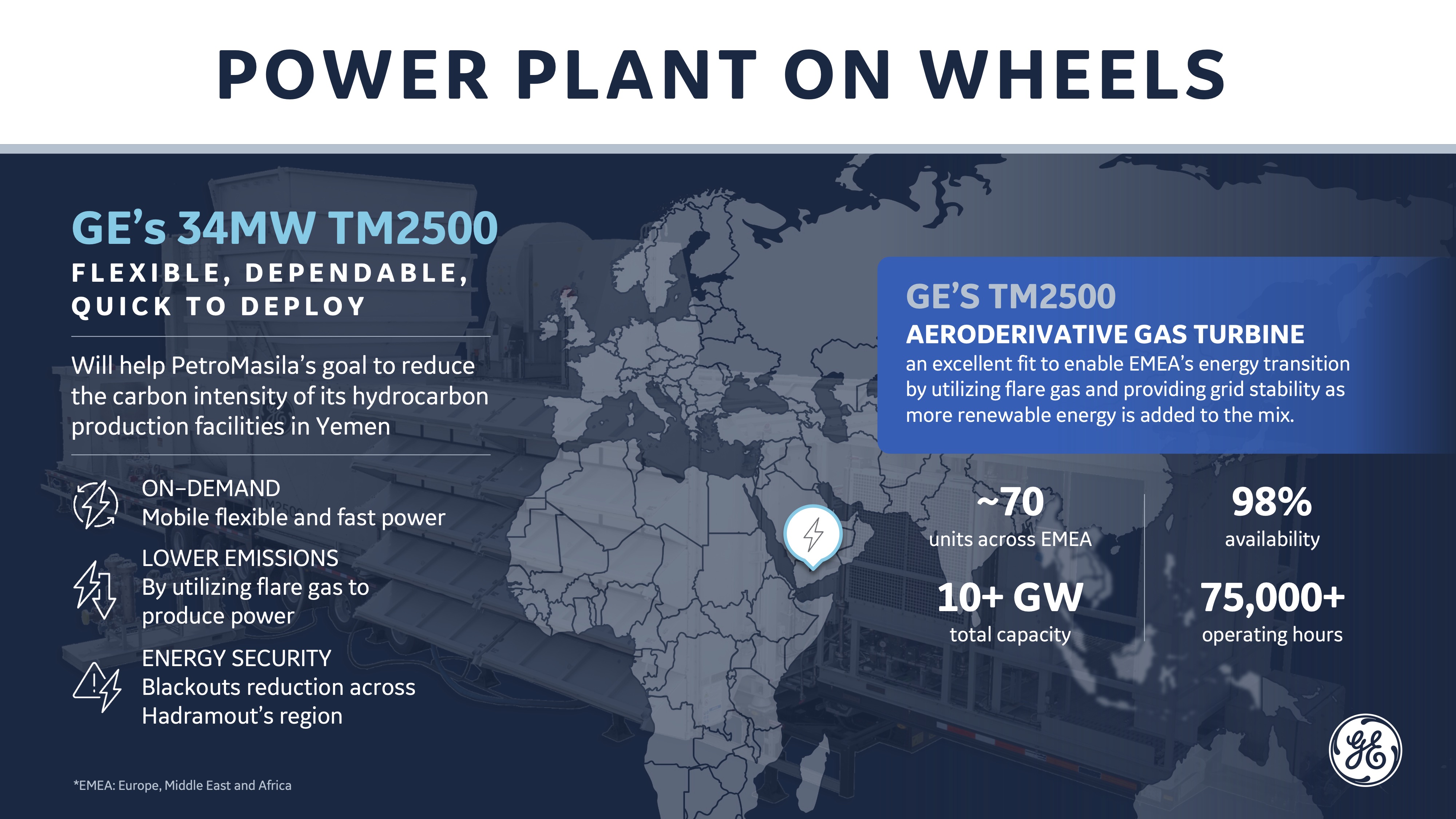

- GE’s TM2500* aeroderivative gas turbine will help PetroMasila transition from diesel to natural gas-based power generation

- TM2500 - GE’s “power plant on wheels” with an ISO rating of 34 MW will be used to provide fast, flexible power to support oil exploration and extraction operations

- Ending gas flaring is central to the broader effort of decarbonizing oil and gas production

- In addition, once interconnected to the local grid, the project is expected to help relieve some of the blackouts experienced in the Hadramout region, after eight years of civil unrest have destroyed or severely damaged the national grid

Yemen - March 27, 2023 –GE (NYSE: GE) today announced an order for fast, and flexible power from Yemeni state-owned Masila Petroleum Exploration and Production Company (PetroMasila), which operates the exploration and production of oil in Yemen. Many oil field operators who flare associated gas - natural gas found in a mixture with crude oil within a reservoir - are making the investments necessary to reduce flaring and lower related emissions. The order includes a trailer-mounted GE TM2500 aeroderivative gas turbine. The TM2500 unit will be installed at Block 14 in the Hadramout region and will be capable of providing up to 34 megawatts (MW) at the site’s conditions.

The TM2500, a “power plant on wheels” will be powered using previously flared associated gas to support PetroMasila’s oil exploration and extraction processes—creating electricity from excess gas. Once interconnected to the local grid, over half of the electricity produced from the unit at Block 14 will be delivered to the grid, providing electricity needed to power homes in Yemen that currently suffer blackouts. The TM2500 unit is expected to achieve commercial operation in 2023.

GE’s highly efficient and flexible TM2500 unit will help PetroMasila to meet its power generation plans by utilizing previously flared associated gas and eliminate the use of diesel, a higher emitting and expensive fuel. Flaring of associated gas is not only an economic waste but also leads to environmental pollution, as it contains methane and hydrocarbons which contribute to increasing greenhouse gases globally.

In 2021, according to the World Bank’s 2022 Global Gas Flaring Tracker Report, 144 billion cubic meters of gas was burnt in flares at upstream oil and gas facilities across the globe, resulting in approximately 400 million tons of carbon dioxide (CO2) equivalent emissions. By utilizing the gas that is currently being flared, the world could make significant progress towards much needed energy security from a readily available source.

Today’s announcement comes on the heels of previous three TM2500 units installed at Block 10 in East Shabwa region of Yemen in 2022. The new units replaced diesel generators, that not only generated 50% more emissions than the gas turbines, but also ran on expensive imported diesel fuel

“PetroMasila is committed to supporting the Yemeni economy by efficiently developing the country’s hydrocarbon resources, and also by taking steps to secure reliable power for the people living in the regions where we operate,” said Mohammed Bin Sumait, General Manager of PetroMasila. “We valued both the long-term and successful collaboration with GE throughout many years. GE’s commitment to move the needle on carbon intensity by providing leading, flexible technology that will help us to reduce our emissions footprint in the future while helping ensure the fast delivery of much needed power for the people in Yemen, is greatly appreciated. Ending routine flaring at our oil production site is vital, both to reduce greenhouse gas emissions and to conserve gas for the generation of electricity in communities which rely on less-sustainable fuels, like diesel, for their energy needs.”

As large-scale power projects take years to develop and build, PetroMasila needed a quicker solution to bring much needed power to the people of Yemen, a country facing challenges that include an electricity sector impacted by a severely damaged distribution and transmission system due to the eight-year-long civil unrest in the country, which has impaired the electricity delivery to a large segment of the population.

“GE’s TM2500 is a great fit for a region with growing energy needs: dependable, quick to deploy, and with a modular configuration that will support PetroMasila’s goal to reduce the carbon intensity of its hydrocarbon production facilities,” said Joseph Anis, President & CEO, Europe, Middle East & Africa, GE Gas Power. “In addition, about half of the generated electricity will help relieve some of the blackouts experienced in the Hadramout region of Yemen over the past years. We are proud to support PetroMasila’s broader efforts to reduce carbon emissions of oil and gas production, while raising the generation capacity for local communities.”

In addition to providing PetroMasila with greater fuel flexibility and lower emissions, GE’s power plant on wheel offers up to 98% reliability. GE’s remote monitoring and diagnostic system will further support efficient and reliable operations. Given the extreme heat, common in the region, the TM2500 will benefit from pulse filters for robust filtration of sand and dust, as well as air inlet chiller coils to increase power output during peak summer months.

GE’s TM2500 is derived from jet-engine technology powering the world’s airlines, and it was developed to deliver fast-track and mobile power. The TM2500 is a mobile, gas generator packaged on a three-trailer system with a top-mounted air inlet filter and exhaust assemblies. The units can be shipped by land, air, or sea to nearly anywhere in the world for quick installation, which allows for quicker operation in locations such as Yemen. In 20-plus years on the marketplace, GE has more than 300 TM2500 units installed in about 30 countries worldwide, totaling over 6 million hours of operating experience.